In our last blog post we revised the concept and benefits of lab automation and how Nagi’s SydLab System is an ideal fully automated platform for high-throughput screening of drugs and substances in C. elegans. Today, we are going to go through one of the components of the SydLab System: the microfluidic Nagi chip for in vivo testing at the in vitro scale.

First things first – Microfluidics?

We call both, the science and the technology, microfluidics but, what is it exactly? Microfluidics is the science that studies the behavior of fluids through micro-channels. Called likewise, the development and manufacturing of micro-devices with chambers and tunnels filled with fluids is also referred to as microfluidics.

But, for what? Microfluidics are commonly used for Labs-on-a-Chip technologies since such small volumes of fluids (we are talking about femtoliters volumes) present an ideal behavior for scientific experimentation. Nonetheless, there are many other types of microfluidic chips.

A microfluidic chip is a combination of microchannels, either molded or engraved, connected to a macro-environment by multiple hollowed holes where the fluids can be injected and expelled. There are several benefits in using such technology compared to regular-size devices, like the decrease in sample, chemical and reagents volume, or the possibility of running multiple experiments in parallel due to their small size. All in all, those characteristics help to decrease R&D costs and time.

Microfluidic chips advantages for biological analysis

16.3% – That is how much the microfluidics market will grow until 2028

With a reported $17.9 billion market size in 2020 (Grand View research, 2021), the microfluidics industry is expected to exert a high growth rate during the next few years due to the convenience of such technology. The main market drivers are the capability of microfluidic technologies to speed up processes, and the lack of specialized personnel in the sector, making microfluidics even more attractive due to its user-friendliness and automation possibility.

In particular, microfluidic devices are expected to exert a CAGR of 20.5% in the next five years driven by their multiple applications for fast and resource-efficient drug discovery and biological system’s analysis (Fortune Business Insights, 2019). Additionally, when segmenting the microfluidic devices market, microfluidic chips are still leading the race due to their multiple applications, also exerting the highest growth rate driven by its cost-effectiveness and device friendly integration (Fortune Business Insights, 2019).

Experts point out the still lack of awareness of such technologies as the main pain point for the market, since there exists a lack of knowledge of how to use it and, more importantly, how to integrate it in the processes.

Meet the Organism-on-Chip technology – Easy. Fast. Ethical.

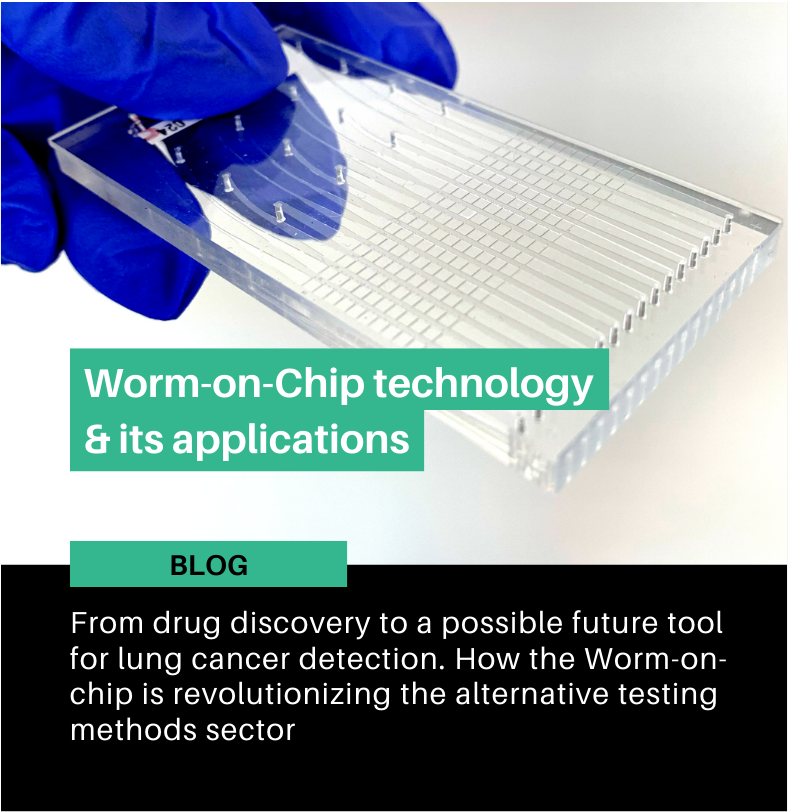

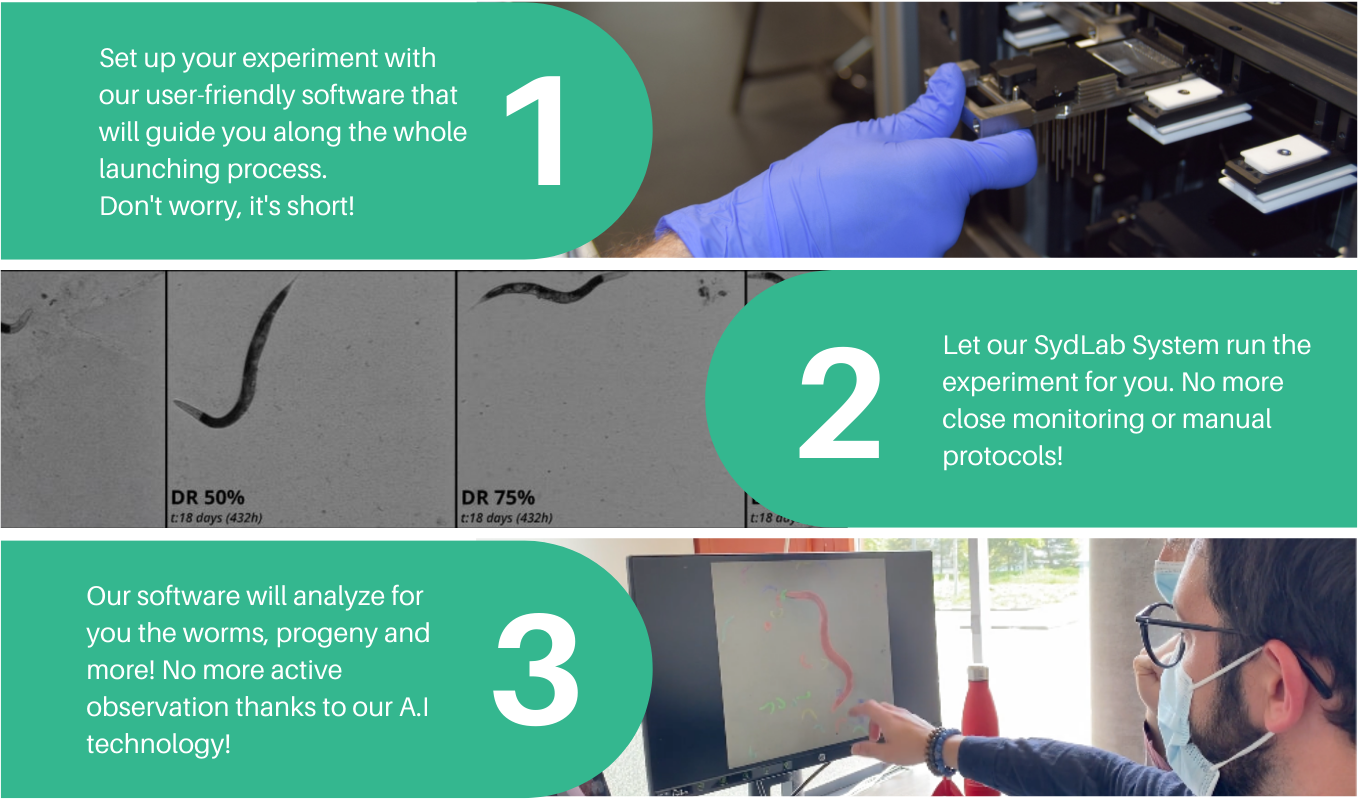

Nagi’s Organism-on-Chip technology introduces a paradigm-shift in C. elegans-based drug and chemical testing. We completely replaced the traditional manual protocols of C. elegans research by standardized operations within the Nagi Chips – disposable microfluidic cartridges – integrated in our fully automated laboratory device, the SydLab System.

Nagi’s technology was developed in harmony with the current restraints that professionals face everyday with the aim of speeding up R&D processes and providing a useful solution to researchers and companies.

Thanks to state-of-the-art microfluidic technology, the Nagi Chips define a new standard for worm culture and treatment, offering superior control of C. elegans feeding, culture and treatment conditions, programmable drug/chemical treatments or washing in every chip channel at any time-point, with a minimal consumption of liquids and compounds.

Our microfluidic technology allows large-scale studies for the parallel characterization of multiple drugs and chemicals in different C. elegans populations. The SydLab System provides fully-automated culture, treatment, imaging and analysis of the worms over long-term experiments. The high-content information and image analysis algorithms allow longitudinal observation at the individual level to evaluate phenotypic readouts such as worm growth, survival, and fertility at the whole-organism level.

Get to know the Nagi Chips

and… How does it work?

Worms are automatically injected into the SydLab device and confined within dedicated chambers of the Nagi Chips. They are then continuously fed with E. coli solution and can be exposed to the test compounds according to the treatment plan defined by the user. The pictures of each microfluidic chamber are collected via time-lapse microscopy at desired frequency.

All in all, Nagi’s system offers a 360° solution for your C. elegans studies, standardizing and automating the whole process, from the experiment initiation until the reporting process. Having completed multiple successful service projects and after validating our technology with Bayer CropScience, the integration of our SydLab System in your lab is now a close reality.

Contact us for more information about the pre-order period here: